Industry Challenges

Information Challenges – When it comes to enhancing productivity, ensuring that manufacturing workforces have the information they need to be successful is crucial. This challenge comes in many different forms. It may be that employees are missing work instructions for the task at hand, have collected an abundance of data that cannot easily be interpreted and used, or are simply not able to trust the quality of information due to a profusion of versions. Whatever the root of the issue, when the workforce lacks the information it needs to produce high-quality output in an efficient manner, productivity suffers.

Related Productivity-Enabling Technologies -Technologies that enable data connectivity, convergence, and real-time correction are needed to overcome information challenges. From the ubiquitous sensing technology that gathers information to analytics & cloud computing that help disseminate it, these technologies empower the workforce to better access and act on the data it requires.

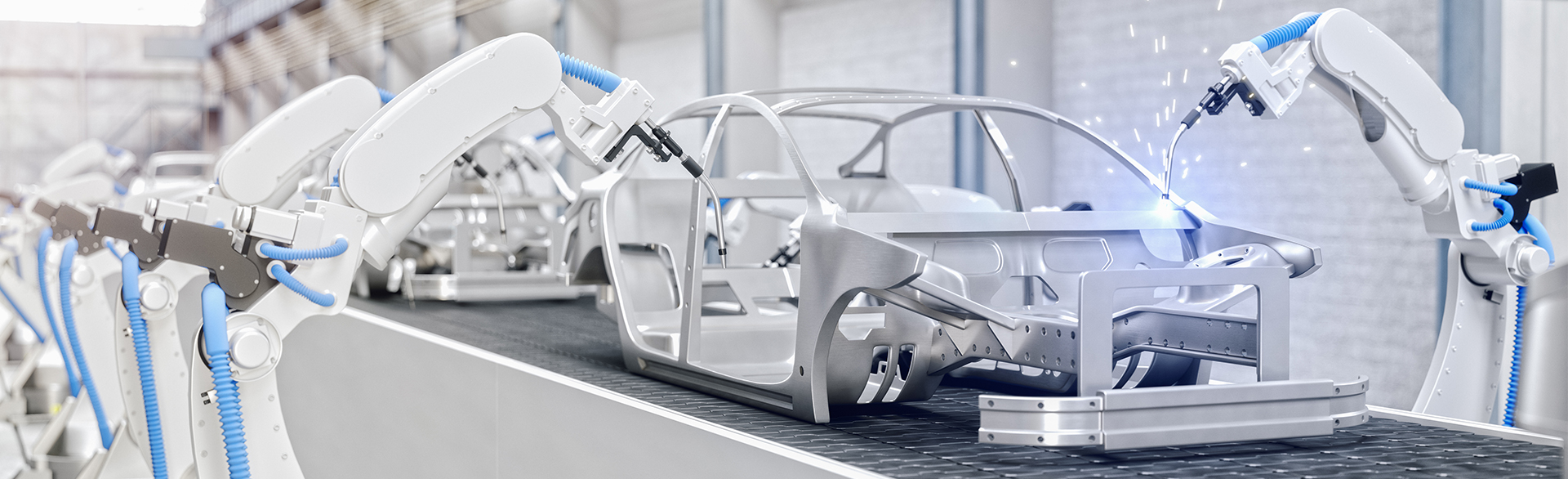

Equipment Maintenance and Upkeep – Unexpected repairs that result in unplanned downtime are major drains on manufacturing productivity. With production depending on sensitive and widespread machinery, one malfunction can slow down an entire production flow in just minutes. Part of the issue is that many manufacturers are relying on reactive rather than proactive management, resulting in difficulties diagnosing problems, rising maintenance costs, and lower productivity.

Workforce Shortage Challenges – The complexity of manufacturing continues to increase, yet the availability of skilled workers entering the industry is declining. We are witnessing a downward trend that could directly impact wage inflation and a talent war that could negatively affect overall productivity and profitability. Now is the time companies need to build a culture of learning, mentoring and knowledge retention and implement digital technologies to attract the digitally-adept new workforce.

Safety Hazards – In an industrial manufacturing environment, ensuring workforce safety must always be a check to pursuing increasingly ambitious productivity goals. From the air quality of the manufacturing environment, to exposure to extreme temperatures, noise levels, and a number of ergonomic issues—such as manually lifting heavy objects—all of these are critical safety considerations that will negatively affect productivity if not properly managed.

Related Productivity-Enabling Technologies: Wearable computing devices, powered by a manufacturing ecosystem that supports edge computing, can provide real-time updates on the status of each member of the workforce to proactively prevent injury. Visual work instructions and Augmented Reality training also ensure that workers are properly and safely trained before undertaking manufacturing tasks.

Equipment

- Servers

- Printers

- Specialty Equipment

Specialty Services Provided

- Custom solutions for specialty invoicing for 3rd party payment company

- End of lease flexibility

- Early buyouts

- Flexible payment structures

- Special equipment buyout needs

- Preferred leasing partner for more than 10 years